Cut To Shape

At Visual Plastics we cut our acrylic using several methods in our factory to give you the best possible finish. These methods include: sawing, CNC routing and laser cutting. We can produce any shape or size you require and in any quantity using computerised beam, panel saws and computer numeric control routers. There is no job to large or small for our team!

Find a Faster, Easier Source of Perspex Cut to Size in Sydney

Finding perspex cut to size in Sydney isn’t always as easy as it seems when you first come up with an idea for a new project. Whether it’s a brand new sign for the foyer or reception area or a custom display stand for a new product line, there are many occasions when you will need acrylic or plastic cut and assembled into specific shapes. Unfortunately, it’s not the kind of activity you can easily undertake on a “DIY” basis, and many of the custom fabricators you find may only offer limited services. For very large or very small projects, you may hear a polite but firm “sorry, we can’t cut that.”

Not at Visual Plastics. Recognising the frustrations many feel when they need an accessible, dependable resource for plastic cut in the shapes and sizes they need, we created a true “one-stop shop.” We do it all, from working with clients on design ideas to carrying out installation in the Sydney area — a service you won’t find with many other fabricators. With extensive and modern equipment, including CNC machines and laser cutters, we’re perfectly positioned to bring projects small and large to life. Let’s explore everything you need to know about what we can do and why we’re the right choice.

The Importance of Laser Cut Plastics

Not everyone offering plastic cut to size in Sydney, such as Perspex, can offer the advantages that come from choosing a business with proficiency in laser cutting. Although not perfect for every application, it’s capable of bringing many ideas to life. Why choose a provider with this technology?

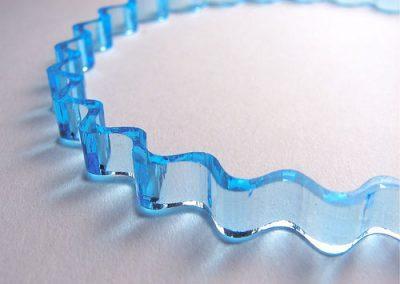

- Precision. Laser cutting delivers highly precise edges and can achieve angles that would prove difficult for other cutting machines. For unique one-off designs, laser cutting offers versatile results.

- Turnaround times. The nature of computer-controlled laser cutting is such that you can enjoy results very quickly. Even on higher production runs of cut to size Perspex, laser cutting occurs so quickly on acrylics that the delays are smaller than with similar processes.

- Suitable for unique applications. Do you have an idea that doesn’t seem possible with traditional cutting techniques, such as items that have punched-out sections? Laser cutters put those products within reach.

Problems You Can Address with Acrylic Cut to Size in Sydney

What can you accomplish with our assistance? Although many people come to us with ideas for business projects, it is also possible to solve a broader range of problems when you can access reliable perspex cutting. Some of those issues could include:

- Replacing damaged or worn out acrylics in regular use. For example, some of our clients have come to us asking for assistance replacing Perspex windscreens for their boats. We can take your measurements and ideas and turn them into an item ready for a quick repair.

- Sealing up draughty old windows in the cooler months. Some homeowners custom-cut some types of acrylic plastics to fit their windows, then affix them to the frame with screws to provide a physical barrier against escaping air.

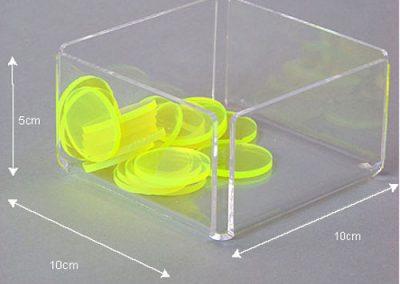

- An inability to find storage and display solutions for unique items. Have a collection to display at home, or want to make an impressive stand for a product you want to put on sale? Perspex in a custom size could be the way to go.

Common Mistakes People Make with Plastics Cut to Size

We strive to make our service as easy to use and as responsive as possible. However, it’s prudent to make sure you have a good sense of what you need before you place any orders. Watch out for these common errors:

- Getting your measurements wrong. Remember the adage “measure twice, cut once”? Measure many times to guarantee you order the correct dimensions.

- Misunderstanding or not knowing about some of the limitations of cutting machinery, such as minimum spacing. Some designs may be too complex for certain machines or materials.

- Choosing the wrong type of plastic. Did you know perspex is a specific type of plastic? There are many kinds of acrylics, and not all of them prove suitable for every project. When in doubt, ask our team to suggest what would work best for your idea instead of making a choice based on a hunch.

What Sets Visual Plastics Apart Regarding Custom Perspex in Sydney?

Ultimately, you will have to choose a pertinent business to receive the finished products you need. What makes Visual Plastics the best choice out there, aside from the technologies we covered earlier?

- We have more than two decades of experience ready to use in the execution of your project. Over 21 years, we’ve seen many advances in this industry, and we’ve kept up with them all to provide our clients with the benefits of our comprehensive understanding.

- Visual Plastics does it all — including installation. What if you only have a basic idea? We’ll work with you to refine that idea into a design, before selecting the appropriate material and cutting plastics to the exact size you need. When it’s all done, we’ll install it safely and securely on site, too.

- We minimise delays. With many machines at our disposal, we work quickly, so even projects on tight deadlines can rely upon our skills.

What to Expect from Visual Plastics As Your Perspex Cutters

When you choose to engage our services, what kind of process should you expect? What do we do to guarantee your satisfaction? Here’s a quick look at what our customers experience when ordering from Visual Plastics:

- Friendly and clear communication. We’re collaborating on this effort together, after all. We believe in speaking plainly about the details, so we’re always on the same page and working in concert.

- Flexibility and understanding, and a willingness to work with clients across a wide range of potential budgets. We understand that ideas change, and so do personal and business circumstances. Visual Plastics accommodates shifting needs with ease.

- Superior results reflective of attention to detail and care. See some of the results of our work for a glimpse at the quality custom cuts we produce daily.

A Short Buyer’s Guide to Our Perspex in Sydney We Cut to Size

Ready to get started with placing your order? We look forward to working with you soon. Explore our quick buyer’s guide to get a sense of what it will be like when you want to request a custom cut:

- Choose the type of cutting method you will need. These may include laser cut Perspex, CNC guided machines, or even engraving on plastic.

- Select your thickness. The sheets we cut to size start at 2440x1220mm, with thicknesses as thin as 2mm or as thick as 40mm. Not sure what thickness will be best for your application? Let us know, and we’ll help out.

- Choose your colour or mix and match. We have dozens of colours to choose from, enabling many exciting design outcomes. Once you’ve made these selections, we can move on to the actual design process, or begin cutting right away if you simply need the custom cuts for your projects.

About Visual Plastics

A local and independent business, Visual Plastics grew out of a simple yet frustrating event. We found ourselves in a position where we needed some acrylic perspex cut to size for a particular application. No matter how hard we tried, we simply couldn’t find a service provider with the tools and experience to deliver the product we needed. Recognising a gap in the market — and seeing that other cutters weren’t doing as much as they could — we launched Visual Plastics, an end-to-end design and fabrication service intended to make it easier to obtain cut to size plastic for any application.

Contact us today with your design ideas or let us know what you need right away.